At the 9th International Summit on Power Battery Applications (CBIS2024), ENP and WJM made a special appearance with their pre-nickel-plated steel. The summit brought together representatives from domestic and international industry regulators, research institutions, lithium battery manufacturers, and key players across the entire supply chain (including materials and equipment providers), all working together to advance the development of the lithium battery industry.

On November 19, at the "Battery Material Innovation and Industrial Applications" themed forum (sponsored by Zhenli New Materials), Guo Tianzhu, Product Director of Jiangsu WJM Technology Co., Ltd. (Vigorous Metal), delivered a keynote speech titled "Pre-Nickel-Plated: Specialized Material for New Energy Battery Shells."。

Guo Tianzhu, Product Director of WJM, delivers a keynote speech on specialized materials for new energy battery cans.

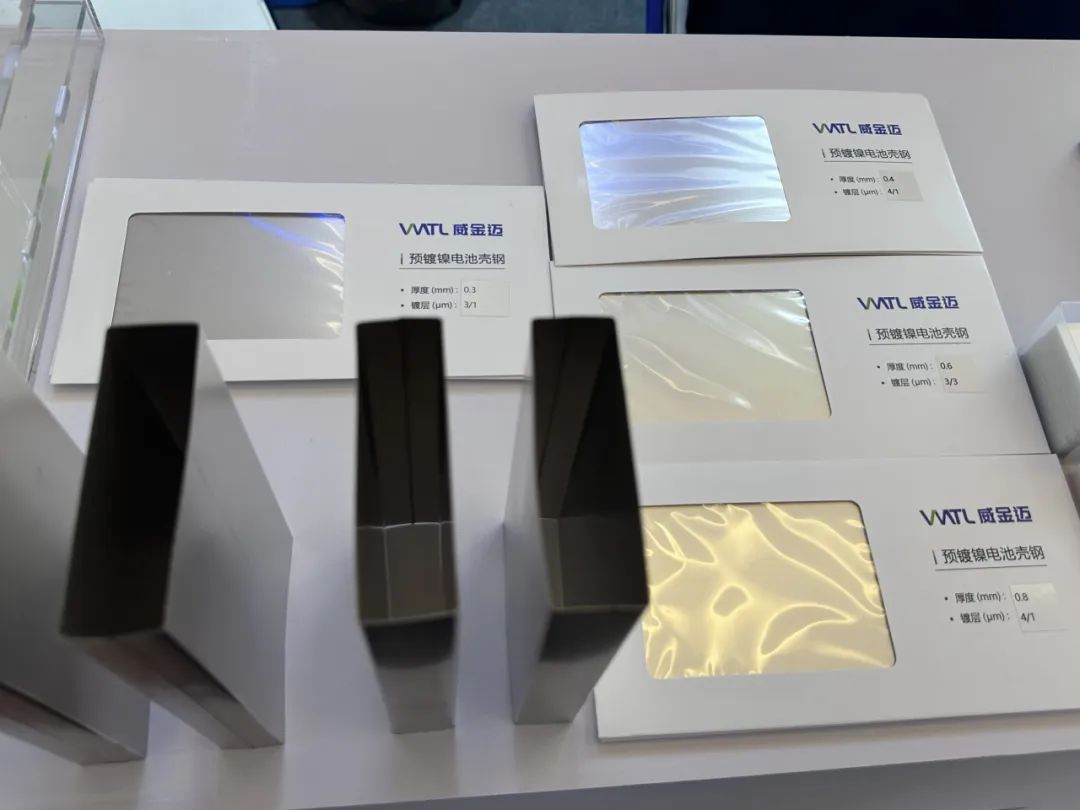

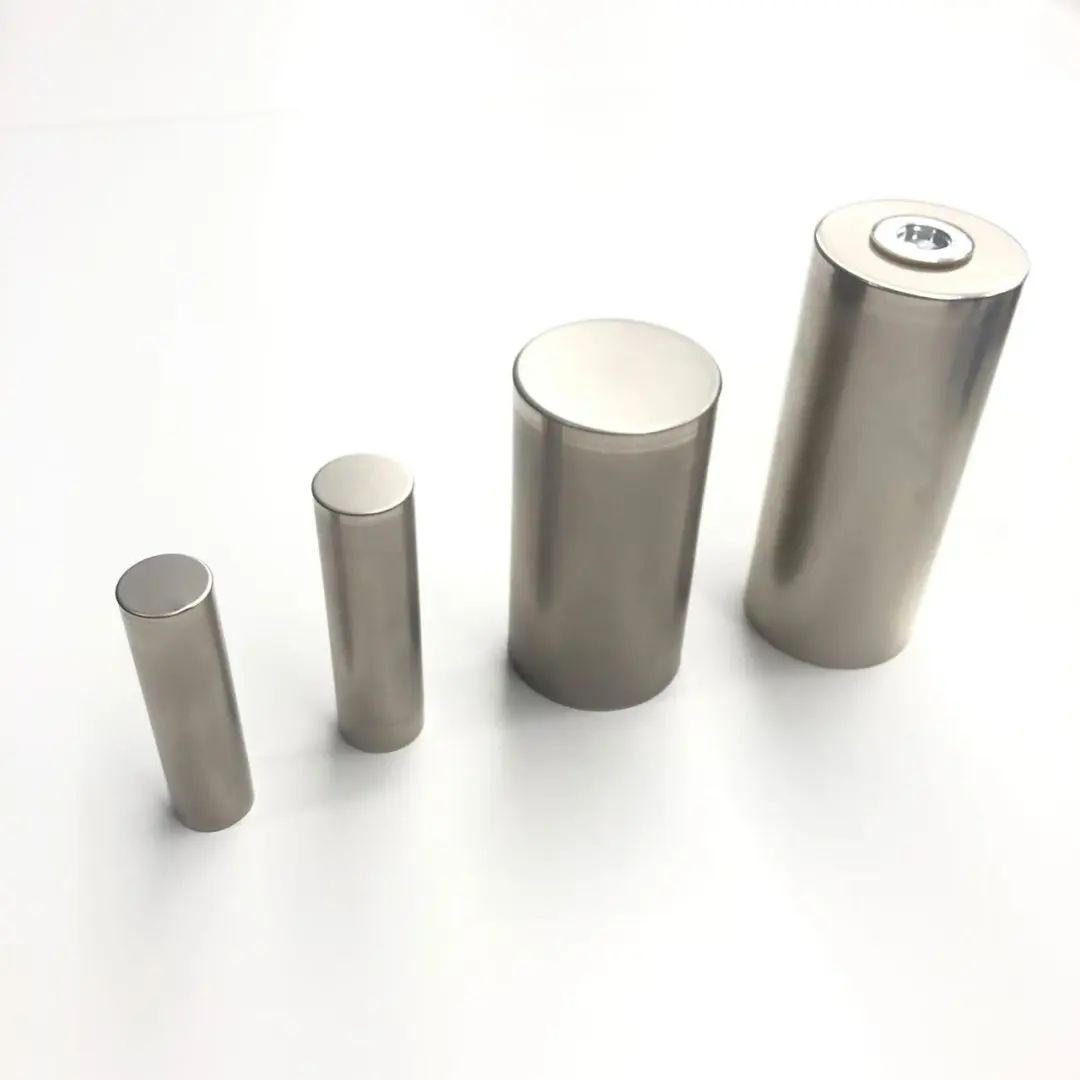

Product Director, Mr. Guo presented the performance characteristics of pre-plated nickel steel strips and shared their application prospects in new battery formats like blade batteries and 46-series large cylindrical cells. In battery manufacturing, pre-plated nickel steel strips deliver higher energy density, longer cycle life, and more stable performance. Notably, comparative analysis of technical parameters demonstrates that WJM's products achieve domestically leading comprehensive performance.

WJM's pre-nickel-plated steel generated tremendous interest at the summit, with their exceptional performance characteristics and broad application potential resonating strongly across industry attendees.