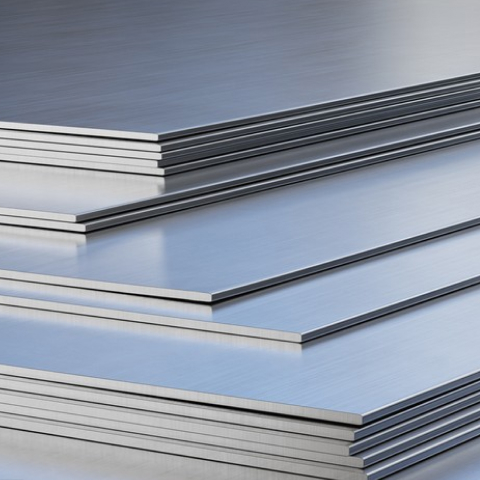

PRODUCT INTRODUCTION

After pickling of hot rolled steel to remove the oxide skin for cold continuous rolling, the finished product is cold rolled, to continuously stretch the steel causing cold hardening to increase strength, hardness and toughness. This will cause stamping and forming performance to deteriorate therefore can only be used for simple forms of parts.

PRODUCT ADVANTAGES

-

Cold rolled steel production process has no application of heat, so there is no pitting and iron oxide and other defects. The surface quality is smooth with a silver-white finish.

-

The dimensional accuracy of cold rolled products are high, and the thickness difference throughout the product is generally no more than 0.01-0.03mm or less. This fully meet the requirements of high-precision tolerances.

-

Cold rolled products have very good mechanical properties (e.g. higher strength, yield strength, forming and drawing properties, etc.)

-

Cold rolled products are produced at high speed continuous manufacturing for high productivity.

-

Cold rolled products perform with reliable durability, long life compared to galvanized steel. Compared to galvanized steel, cold rolled steel have a higher resistance to heat resistance, less prone to discoloration at high temperatures.

PRODUCT DESCRIPTION

-

SPECIFICATIONS

SPECIFICATIONSThickness: 0.2 - 4mm

Width: 600 - 2000mm

Length: 1200 - 6000mm.

-

APPLICATIONS

APPLICATIONSCold rolled steel products are mainly used in: hardware processing, automobile industry, home appliances, industrial packaging, shelves, pipe making, tinplate and other industries.

CONTACT US

IF YOU HAVE ANY QUESTIONS ABOUT OUR PRODUCTS, PLEASE CONTACT US

-

Email

terry@enp-china.com

-

Company Address

Suite 903-905, Building B, Lanyun Culture Center, Lane 899, Panlong Rd, Qingpu Disitrict, Shanghai.