Exhibition Review: Pre-Nickel Plating Technology Leadership, Strategic Cooperation Empowering the Future Market of Battery Steel

2025/03/28

ENP NEWS

As global focus on environmental protection and sustainability increases, large cylindrical power batteries and pre-nickel-plated steel are seeing unprecedented growth opportunities. Shanghai ENP's Battery Steel Project Team specializes in pre-nickel-plated battery steel materials, using high-profile exhibitions and industry networking to deepen ties across the new energy battery supply chain, to further enhance the market influence of the company's pre-nickel-plated steel.

01

On March 25-26, the 2025 New Energy Battery Structural Components Industry Summit and the Cell Casing, Liquid Cooling Plate & Battery Pack Lightweight Forum was held in Shanghai.Alex, General Manager of the Battery Steel Division of ENP, along with Deputy General Manager Wei Naiyu, Key Account Manager Faith Fu, and others, attended an event hosted by Bu Shuaihu, Sales Director of Jiangsu WJM, and global industry leaders and experts focused on innovations in battery structure, breakthroughs in thermal management technologies, and lightweight solutions.

On the morning of March 25th, Bu Shuaihu, Sales Director of Jiangsu WJM, delivered a keynote speech at the "New Energy Battery Structural Components Industry Development and High-Level Dialogue" forum. His presentation provided attendees with a more intuitive understanding of the outstanding performance and promising industry prospects of pre-nickel-plated steel.

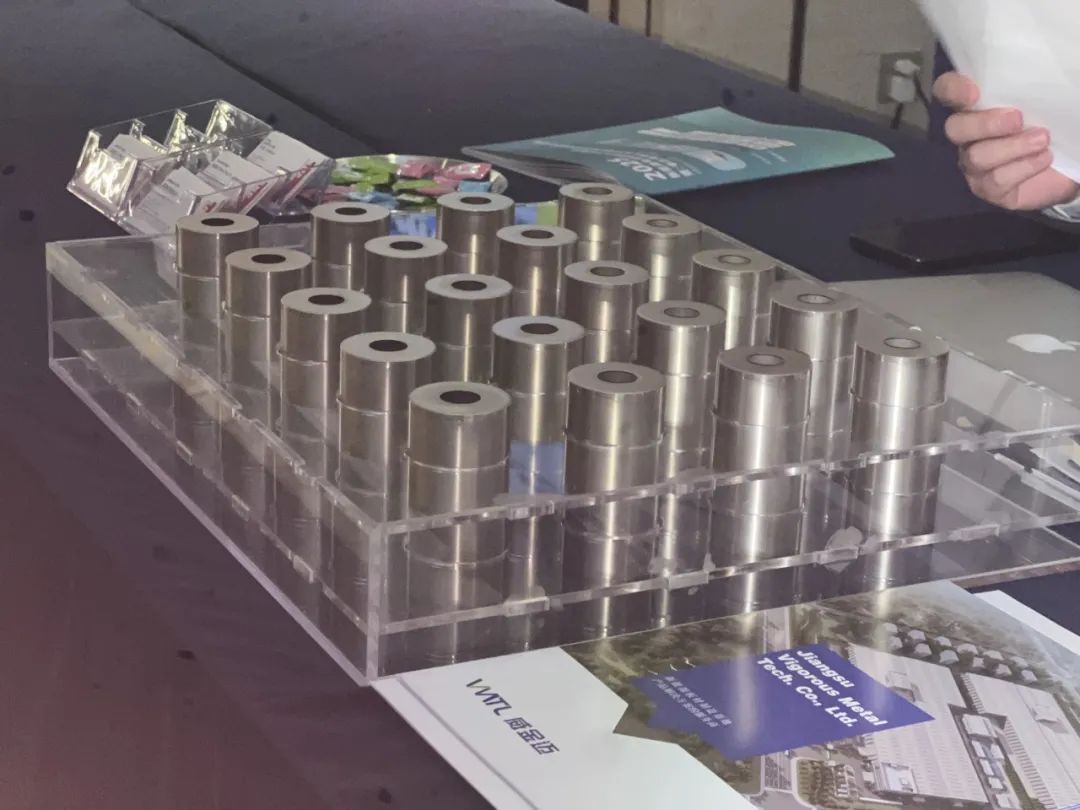

At the summit, the teams from ENP and WJM actively engaged with various stakeholders in an open and collaborative manner, creating a lively atmosphere on site. Their interactions not only strengthened existing partnerships but also expanded potential avenues for future cooperation.

02

Pre-nickel-plated steel is produced based on electrochemical principles, where a uniform and dense nickel layer is deposited onto the surface of low-carbon or ultra-low-carbon steel through an electric current in a specific plating solution. Subsequently, processes such as heating, heat preservation, and cooling are applied to achieve the desired iron-nickel alloy layer along with the required physical and chemical properties.

Upgrading the casing material of energy storage batteries to pre-nickel-plated steel will significantly enhance product performance. Specifically, it will bring the following advantages to the product and the company:

Pre-nickel-plated steel are formed in a single step using multi-roll rolling equipment or stamping equipment, followed by welding. They offer low processing costs, excellent corrosion resistance, and good weldability.

Using pre-nickel-plated alloy steel significantly enhances strength. The tensile strength can be increased from 160–180 MPa (typical of aluminum alloys) to over 500–600 MPa, meeting the strength requirements for high-energy-density batteries and automotive CTC (Cell-to-Chassis) applications.

The battery casing thickness can be reduced from 0.5–1.0 mm (aluminum) to 0.35–0.40 mm (using pre-nickel-plated high-strength or ultra-high-strength alloy steel). Compared to aluminum strips, pre-nickel-plated alloy steel enables approximately 2/3 reduction in thickness while maintaining comparable casing weight.

The melting point of steel (1600°C) is significantly higher than that of aluminum (660°C), effectively preventing battery short-circuit fires and greatly improving safety.

03

The global new energy industry is undergoing a structural transformation, with pre-nickel-plated materials, as a core component of lithium batteries, experiencing explosive growth.ENP has accurately captured market trends and established an in-depth strategic partnership with Jiangsu WJM. Its independently developed third-generation pre-nickel-plated steel has garnered significant attention across the industry chain at recent sector summits.

CLICK HERE TO VIEW MORE

ENP and WJM: Pioneering Battery Material Innovation, Delivering Reliable Performance!

ENP Leverages Precision Manufacturing Expertise and End-to-End Solutions in High-End Building Materials, ENP has established a smart warehousing and high-efficiency distribution network covering East China and South China, accumulating extensive experience in developing scenario-based new energy solutions.

Jiangsu WJM, an innovation leader in new energy metal materials, has established a fully integrated production line with an annual capacity of 210,000 tons of pre-nickel-plated steel. Its product performance metrics meet internationally advanced standards.

The strategic partnership between ENP and WJM will deeply integrate both parties' technological R&D capabilities and market channel advantages, Together, we explore new horizons in energy storage, advancing toward a greener, smarter future.

ENP will continue to leverage pre-nickel-plated technology as a cornerstone, deepening its "capacity + R&D" collaboration with WJM to build a global material ecosystem spanning new energy, healthcare, and energy storage. This initiative aims to empower "Made in China" in securing a pivotal voice within the global high-end industrial chain!